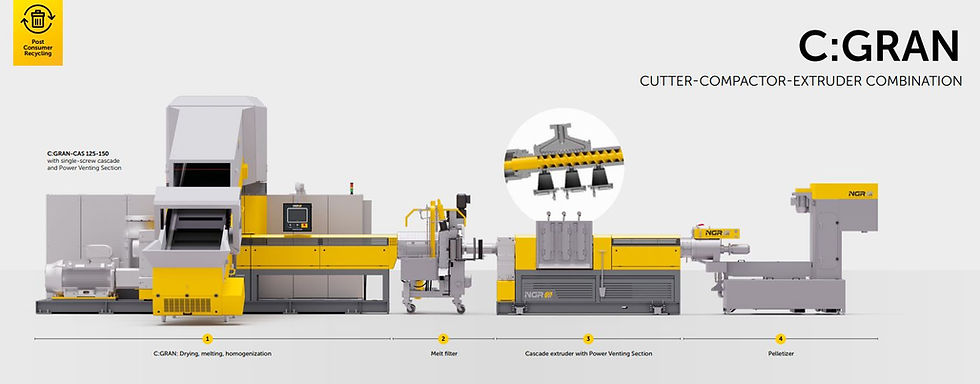

The NEW updated C:GRAN

Higher Throughputs with the best Venting performance on the market!

The C:GRAN is distinguished by its enlarged cutter bin with advanced cutting geometry. The combination of a fast-moving rotor blade with efficiently arranged guides ensures a continuous energy input into the material. This ensures that the material is optimally prepared for the subsequent extrusion process. The C:GRAN is also an ideal option for a component of a cascade extruder or a compounding system.

Depending on the application, this machine can be equipped with a wide range of melt filters, such as continuous filters, piston filters, backflush filters, etc.

Some benefits of the NEW C:GRAN line:

-

Reduced total screw length to mitigate material degradation and reduce energy consumption.

-

The screw length does not change whether you have 1 filter installed or if you have an optional 2nd filter installed prior to pelletising.

-

Flexibility of different screw speeds in the two sections as they are driven by separate drives to optimize temperature profile and process control.

-

Easy maintenance as the two extruder screws are removable independently which also makes it more cost effective in the long run.

-

There is no risk of seal failure from a fixed inline filtration system.

-

Venting after removal of contamination for best possible venting performance, the C:GRAN provides this with it innovative “Power Venting System”.

-

The best possible extruder venting reduces pellet odour as much as possible during the extrusion process. Add-on Odour reduction systems are also available.

-

Energy recovery and energy retention solutions incorporated as standard on the machine to reduce energy consumption.

-

Special control features that reduce operator intervention such as automated temperature regulation in the cutter compactor to optimize performance and avoid melt downs with no water injection.

-

Output rate up to 3,000 kg/h (6,610 lbs/h) depending on type

-

Preparation of flakes and films with residual moisture up to 12 %

-

Ideal as a component of a cascade or compounding system

-

Depending on the application, this machine can be equipped with a wide range of melt filters, such as continuous filters, piston filters, backflush filters, etc.